FUNCTIONAL TO -200°C AND LOWER

Sealing materials for sub-zero temperatures

Seals often have to withstand extreme loads - including the effects of temperature. A trend can currently be observed in which sealing materials are increasingly required, especially for temperature ranges below -30 °C. Since large quantities of these are usually not required, this primarily applies to seals that are machined in our in-house production.

Materials such as PTFE + compound and UHMWEP can be used down to -200 °C and lower. In order to ensure elasticity, these materials always require an additional sealing element. These so-called preload elements are very often elastomers with different geometries, O-rings have established themselves as the standard geometry here. In order to guarantee a secure sealing function even at extremely low temperatures, extensive elasticity is a prerequisite.

Seal Concept works here with raw materials from its own warehouse, which exactly meet this requirement. For example, a special low-temperature - NBR, an EPDM material - in the colors black and white with FDA conformity available down to -50 °C, as well as various silicone mixtures, which reliably meet the required conditions down to -55 °C.

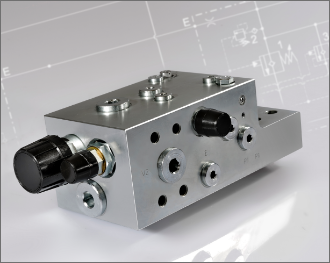

For applications where U-rings and wipers are provided, there is our RedSuperPolymer, the pinnacle of turned seals. RedSuperPolymer is a high-performance polyurethane that makes seals for hydraulic and pneumatic applications even more efficient. This high-performance material has proven itself in difficult application situations. Its excellent temperature properties enable applications down to -50 °C, special low-temperature polyurethanes guarantee perfect functionality down to -55 °C.

The performance of these special sealing materials is impressive: Even at enormous minus temperatures, the elasticity is ensured in order to meet the high requirement profile of a demanding everyday production.